In the world of composite manufacturing, choosing the right process can significantly impact the performance, cost, and durability of your final product. Among the various techniques available, filament winding has gained popularity for its precision and efficiency in producing high-strength cylindrical components. But how does it compare to other composite manufacturing methods? In this blog, we’ll explore filament winding, its benefits, and how it stacks up against alternative techniques to help you make an informed decision. Connova, a leader in advanced composite solutions, provides expert guidance in selecting the best manufacturing process for your needs.

What is Filament Winding?

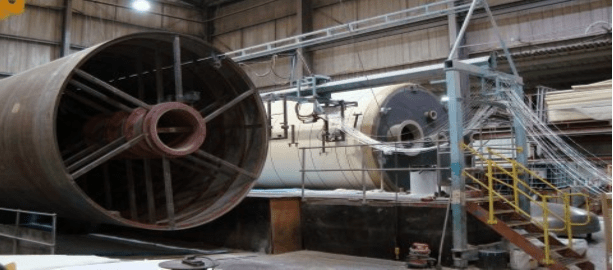

Filament winding is a composite manufacturing technique where continuous fiber reinforcements, such as carbon, glass, or aramid fibers, are wound around a rotating mandrel. These fibers are impregnated with resin during the process to form a lightweight yet strong composite structure. This method is widely used in aerospace, automotive, marine, and industrial applications due to its superior strength-to-weight ratio and cost-effectiveness.

Advantages of Filament Winding:

- High strength and durability: The fiber alignment enhances mechanical properties, making it ideal for pressure vessels, pipes, and structural components.

- Cost-effective: Reduced material waste and automation lower production costs.

- Excellent repeatability: CNC-controlled winding ensures high precision and consistency.

- Versatility: Can accommodate various fiber orientations and resin systems for tailored performance.

Comparing Filament Winding to Other Composite Manufacturing Methods

1. Hand Lay-Up and Spray-Up

Overview: These traditional methods involve manually placing fiber reinforcement layers and applying resin via hand lay-up or spray application.

Pros:

- Low initial investment

- Suitable for large, complex shapes

Cons:

- Labor-intensive and inconsistent quality

- Limited fiber alignment control

Filament Winding vs. Hand Lay-Up: Filament winding offers superior mechanical properties, automation, and repeatability, making it preferable for high-performance applications.

2. Resin Transfer Molding (RTM)

Overview: RTM uses a closed mold where fibers are pre-placed, and resin is injected under pressure.

Pros:

- High-quality surface finish

- Good fiber volume fraction

Cons:

- Higher tooling costs

- Not ideal for tubular or cylindrical structures

Filament Winding vs. RTM: While RTM is better for complex shapes with tight tolerances, filament winding excels in producing strong, lightweight cylindrical components at a lower cost.

3. Pultrusion

Overview: A continuous manufacturing process that pulls fiber reinforcements through a resin bath and into a heated die to form profiles of constant cross-sections.

Pros:

- High production efficiency

- Consistent mechanical properties

Cons:

- Limited to linear profiles

- High initial tooling costs

Filament Winding vs. Pultrusion: Filament winding provides greater design flexibility for cylindrical structures, whereas pultrusion is ideal for uniform cross-section parts.

4. Compression Molding

Overview: Pre-impregnated composite materials are placed in a mold and subjected to heat and pressure.

Pros:

- Excellent surface finish

- High production speed for mass manufacturing

Cons:

- High mold costs

- Less fiber orientation control

Filament Winding vs. Compression Molding: Filament winding is better suited for applications requiring high fiber alignment and strength, while compression molding is ideal for complex, high-volume production.

Why Choose Connova for Filament Winding Solutions?

Connova specializes in advanced filament winding technology, offering tailored solutions for aerospace, automotive, and industrial applications. With expertise in precision engineering and composite innovation, Connova ensures top-tier performance and cost efficiency for your projects.

Get Started with Connova Today!

Choosing the right composite manufacturing method depends on your application, budget, and performance requirements. If you need high-strength, lightweight cylindrical components with excellent material efficiency, filament winding is the optimal choice. With industry leaders like Connova, you can leverage advanced filament winding technology to achieve superior results in composite manufacturing.

Need expert advice? Contact Connova today to explore the best composite solutions for your project!